Re-Engineering Crane Parts & Upgrade Services

- Home

- Precision Machining

- Re-Engineering

“Why did they make it like that?” Often when working on machinery we wonder why they make a part in a particular way when obviously if something was just a little shorter or had pulling threads it could be replaced without having to remove all those other components. This costs money and time, two things we all could use more of these days.

While we cannot stress the fact that there are many other factors involved in the engineering of parts besides the ease of maintenance, safety, and product integrity being at the top of that list, there are still many opportunities to improve on a design.

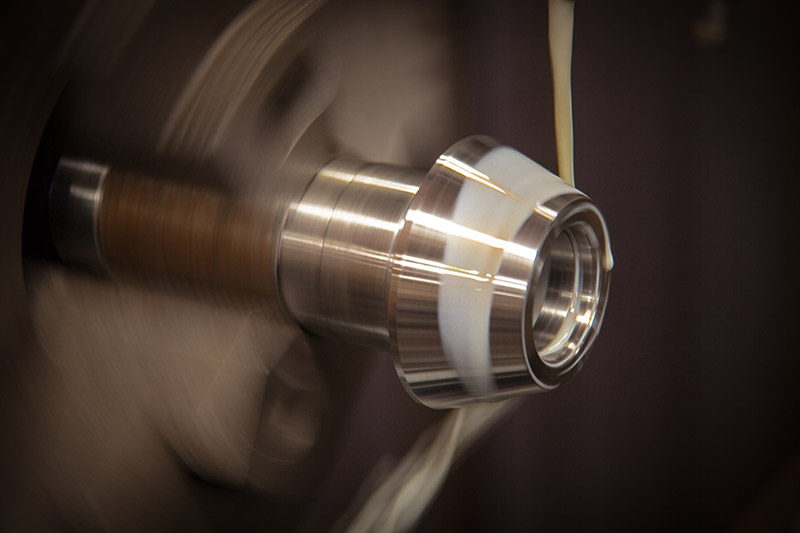

One example of a re-engineered part is a seal surface on a shaft, if the shaft runs daily on a seal surface, with proper maintenance the bearings and mating parts should last for years. Inevitably though, at some point, you start to see oil seeping from the seal, upon removal and inspection you find all components are in good shape except this one surface spinning on the seal has been worn down to a point that replacing the seal is not enough to eliminate the leak. Re-engineering that shaft to have a replaceable wear ring in the location of the sealing surface allows for future inexpensive repairs and significantly increases its life.

Examples of issues and problems which can be addressed by re-engineering:

- Replacement procedures

- Excessive & persistent wear in one area of a part

- Integrity

- Quality

- The life span of a particular part

- Poor fit and function

Examples of some more common revisions are…

- Upgrade the material

- Billet part vs. Fabricated part

- Change a one-piece part into a two-piece with a splined connection

- Add a wear-sleeves

- Machined gear teeth vs. Casted un-machined gear teeth

- Tighten Tolerances

By far the best reason to re-engineer a part is because you see a way to do it better and if you can get it made your way, you can make lots of money with your revised version.

Mitchell Crane will keep your ideas confidential whether you decide to have us produce for you or not. We can work with your budget and offer manufacturing solutions. We can help you make your ideas a reality!

Check out our page on Specialty Precision Machining to see how we can help you with other ideas. View our machine specifications and capacities.